What Pump Should I Use To Pump Alcohol Through A Bag Filter Housing

In between malting, mashing, distillation, maturation, and filtration,, you could say that craft distillers are in the business of transferring liquids.

Distilleries need dependable pumps that fit their production cycle, helping to create a repeatable, consistent, and safe process. Different pump types allow different distilleries to easily transfer and filter liquids depending on their process specifications.

Pumps are used for almost every stage of production, including:

- Bringing in water

- The mashing stages

- Wort recirculation

- Fermentation transfer

- Filling barrels

- Distillation

- Filtration

- Filling bottles

The ii main pump types—centrifugal and positive deportation—offer a wide range of options for varying capacities of liquid transfer. But a distiller chooses a pump based on more than than merely the amount of liquid they're dealing with. Processing stage, pressure, besides as the proof of the distillate or liquid they will transfer matter, too. Other considerations include head capacity, the liquid'due south viscosity, density, and acidity.

Picking a high-quality, industrial forcefulness pump that matches your needs is a smart investment that can help your equipment last longer and work harder.

A Notation on Pump Rubber

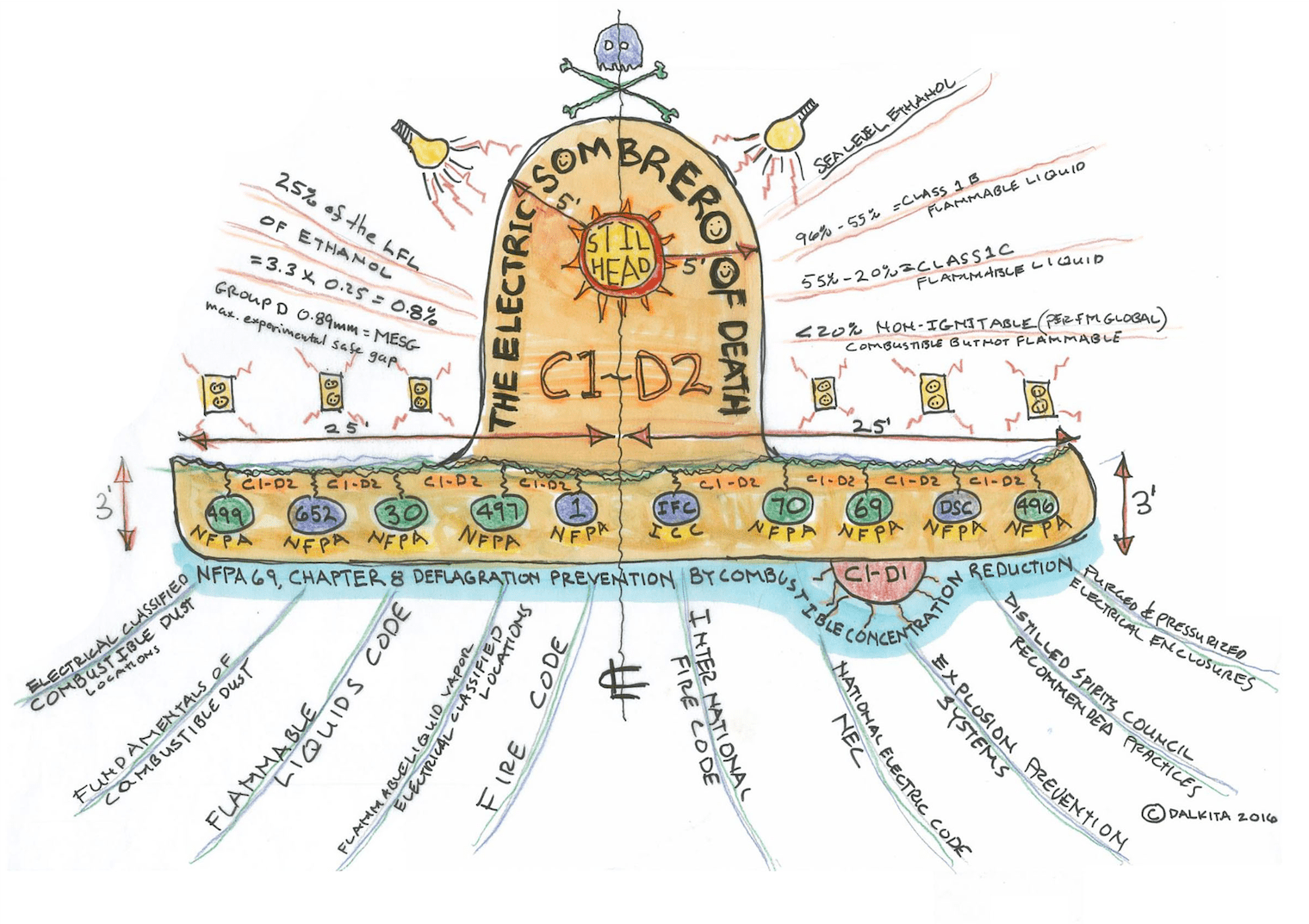

The pumps we carry tin can all be grounded and feature explosion-proof motors. We recently covered why explosion-proofing is an of import rubber precaution in our terminal blog post nigh The Electric Sombrero of Death.

In brusque, calculation electrical equipment to an indoor space containing varying degrees of high-proof liquids and vapors can exist a dangerous combination. Even air motors can cause sparks and need to be placed carefully in your facility.

The distillation process involves concentrated alcohols in liquid and vapor form—both of which are highly flammable and require specialized equipment. Explosion-proof motors in pumps are ane role of the equation for a rubber distillery. Pump and equipment placement is another vital consideration, mapped out by the Sombrero, pictured beneath. Only pumps with explosion-proof motors should be used about a classified area.

Non-explosion proof motors, like VFDs, are however used in some situations, and can be an affordable option. These are not explosion-proof and need to exist fifty-fifty more than carefully placed, taking the Electric Sombrero of Death into consideration.

Scott Moore of Dalkita Architecture and Construction developed an informative model chosen "The Electrical Sombrero of Death" to illustrate the dangers of toxic gases in industrial settings, how to forestall dangerous scenarios, and which guidelines regulate safety.

Back to picking a pump.

To help y'all choose the right pump for your process, take a look at unlike pump use cases and specifications below.

Centrifugal Pumps

Centrifugal pumps are often used to recirculating liquid and transferring high-proof spirits.

How do you lot go all this highly gluey mash to the next stage of production? With the correct pump!

Centrifugal pumps work well with the stages of production that involve high flow-rates (such every bit bringing in h2o) and transferring high-proof liquids. If you're working with a tank, you'll typically hook upwardly a centrifugal pump. Nosotros currently carry four centrifugal pump options

- ½ HP C-Series Pump with Explosion-Proof Motor: With 1/2 horsepower, this pump is a quality option for smaller distilleries producing low volumes. It has a long service life with minimal downtime.

- 1 HP Centrifugal Pump with Explosion-Proof Motor: Medium processes with low flow and low discharge pressure tin can upward the ante to ane horsepower. The C100 Pump has a stainless steel adapter and backplate for optimal longevity. An O-band on the backplate provides a tight, secure seal to the casing for longer, problem-free performance. Because all of the other C100 Pump components remain the same, existing pumps can exist hands retrofitted to the new adapter and backplate.

- 3 HP C-Serial Pump with Explosion-Proof Motor: The 3 horsepower, stainless steel C-series pump can arrange a diverseness of liquids and solids under a range of menstruation weather condition and pressures. The stainless steel torso is hands maintained and is corrosion-resistant. It has 1.5″ tri-clamp connections.

- Cart-Mounted Centrifugal Pump with 3 HP Explosion-Proof Motor: A cart-mounted pump works well for a distillery that needs to use 1 pump for multiple applications and stages of product. It has attachments for a 1 phase VFD and easy hose storage.

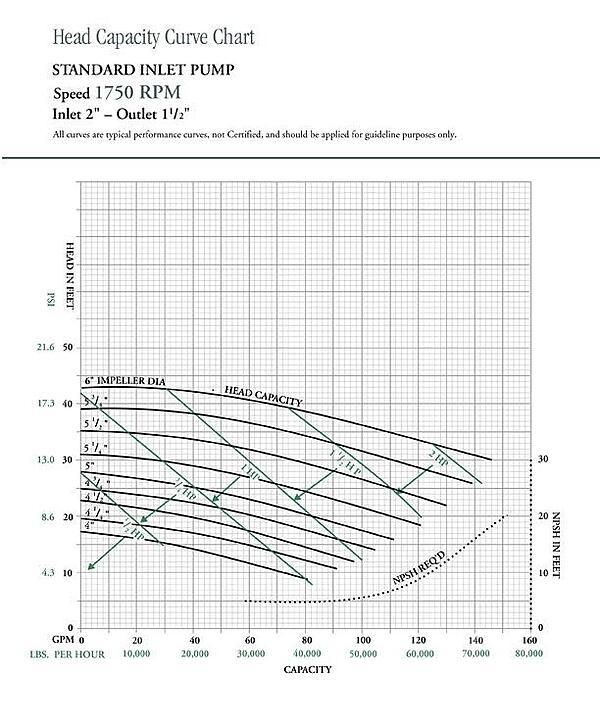

The Head Capacity Curve Chart shows how to determine the power and efficiency of a given pump based on the amount of liquid product y'all intend to transfer. Pay shut attending to impeller bore, which will increase or decrease your pump's efficiency considerably.

Positive Deportation Pumps

Positive displacement pumps ever move liquids at the same speed regardless of pressure conditions. The real benefits hither are that they are self-priming and use suction to produce a abiding period charge per unit. You'll typically see a positive displacement pump existence used to describe fluid out of a tote or barrel. When processing more viscid fluids, positive deportation pumps are the longer-lasting, more efficient choice.

Nosotros carry two rotary positive deportation pumps, both of which are self-priming and can move product from 75 feet away.

- x GPM Cocky-Priming Positive Displacement Pump with XP motor: The ESP-10XP provides up to 15 gallons per infinitesimal of menses with a 3/4 HP one/60/110/1200 explosion-proof motor, Teflon gears, and an integral bypass to regulate flow from 0-xv GPM. The pump is mounted on a portable cart.

- 3 GPM Self-Priming Positive Displacement Pump with XP Motor: The Model ESP-3XP provides upward to iii gallons per minute of flow with a 1/4 HP one/60/110/1800 explosion proof motor, Teflon gears, and an integral by pass to regulate flow from 0-3 GPM all mounted on a portable cart.

For your heaviest, thickest mashes and liquids that take a higher percentage of solids—like grain mixtures for rye, whiskey, and bourbon before fermentation—Screw Pumps, Diaphragm Pumps, or Flexible and Impeller Pumps are the way to become. They're built to handle fluids in completely separate compartments from the pumps' more vulnerable functional parts, keeping your equipment clean while getting your liquids where they need to go.

Desire to learn more? Make it touch to speak with one of our supply professionals about long-lasting pump options and other essential equipment.

Ask the Experts

What Pump Should I Use To Pump Alcohol Through A Bag Filter Housing,

Source: https://proof33.com/how-to-pick-the-right-pump-for-your-distillery/

Posted by: gallaghermathe1984.blogspot.com

0 Response to "What Pump Should I Use To Pump Alcohol Through A Bag Filter Housing"

Post a Comment